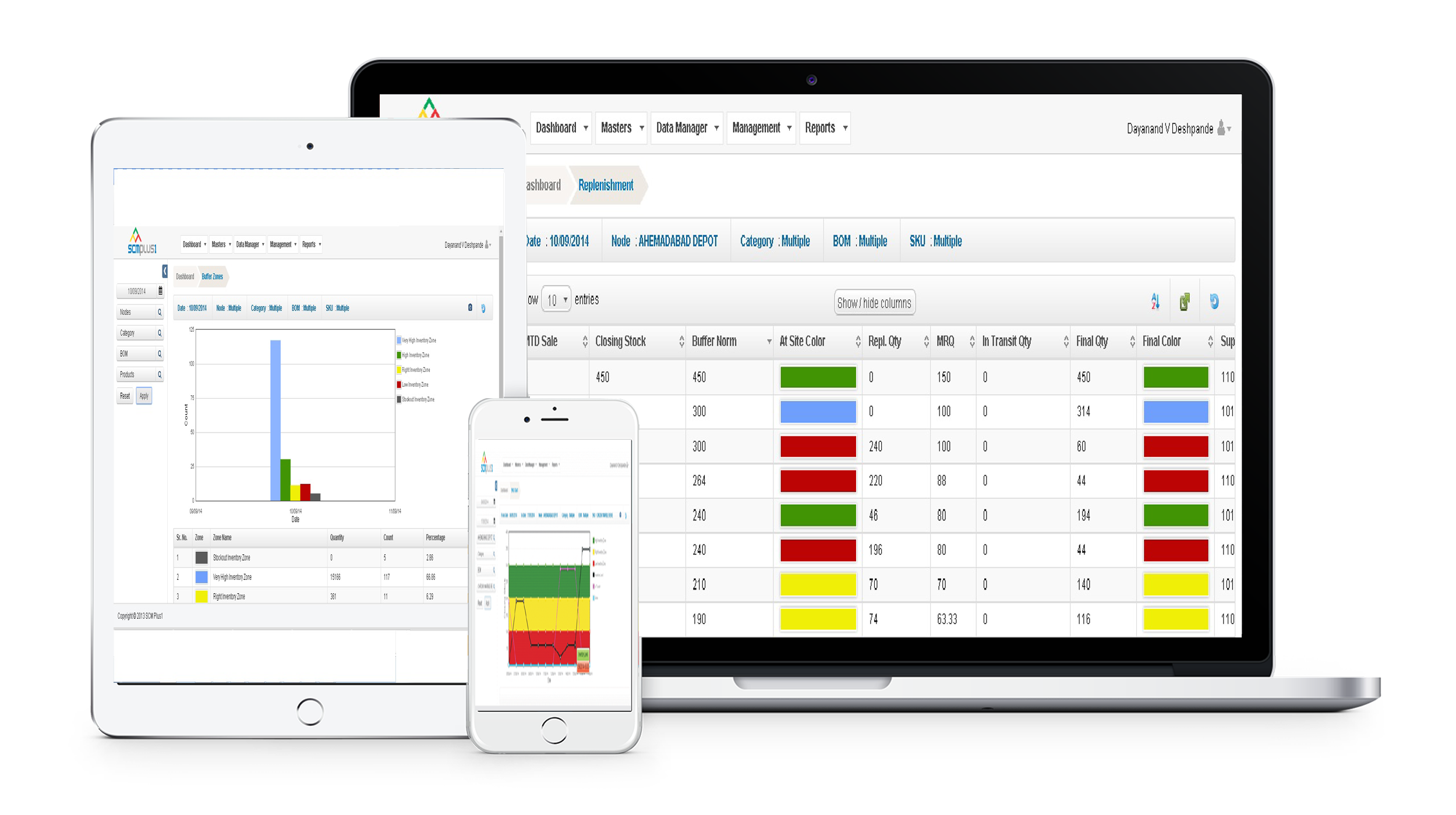

Presenting...Cloud based Supply Chain Replenishment and Execution Software Product.

Cloud based SCMPlus1 dramatically improves forecast execution by addressing well known functionality gaps in MRP and ERP systems. SCMPlus1 adds an entirely new set of capabilities to supply chain organizations; capabilities that transform the way planners, buyers and suppliers collaborate, execute and measure supply chain. Know the status of your supply chain in easily understood colour zones. Blue -very high inventory, Green -high inventory, Yellow -right Inventory, Red -low inventory and Black-stockout inventory zone.